Telephone: 408-839-5569

Email: (Click Here) Andrew@JaguarSpecialties.com

Last Update 7-2-24

|

Getting the power back there, and

being a little shifty.....

Part 6 - Driveline and shifter Go on to Part 7 - Start-up and Air Intake (Click Here)

(This is the sixth in a series of articles on installing the later Gen4 LS engine packages in our Jaguar cars. Check back from time to time for an update) Driveline As I mentioned in an earlier article, the 6L80E transmission output shaft is a little different than anything we had worked with before. More specifically, modern drivelines are relying less on U-joints and more on rubber couplings to link the transmission to driveshaft and driveshaft to diff. This really only works on cars with fixed (IRS) differentials as the output of the trans and the input to the diff need to be perfectly aligned, pointing right at each other. For the Jag installation here, that wasn't really possible, but like earlier conversions, the two points were parallel to each other (within 3 degrees), which is what we need. Here is a pic again of the 6L80E output and what we have to deal with- the 3 finger yoke there is fixed so we can't use a driveshaft with a slip yoke at the front (and even removing that fixed yoke doesn't provide enough splined shaft for a slip in yoke):

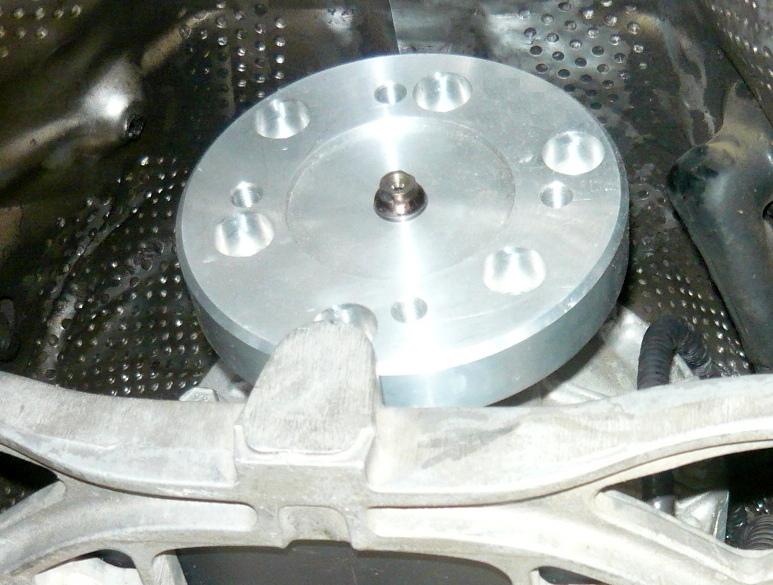

The answer to this dilemma came in the same approach most 4WD trucks use- a driveshaft with a flange at both ends and the slip feature in the somewhere in the main body. We don't really use a lot (if any) travel in the driveshaft itself, but some length flexibility is needed for installation and minor movement in use. And to make it all work we went to where else?? The LS aftermarket of course. One of the main driveline suppliers out there makes a keen adaptor flange that converts this 3 finger output into a threaded 4 bolt flat interface to take a standard driveshaft flange yoke. And here is that piece, installed on the output.

The piece has 6 counter-bored holes going to the trans (we use just 3 of them; the other 3 are for a different application). And then the 4 threaded holes on the driveshaft side take a standard Spicer 1310 flange yoke. So 3 allen head screws and matching nuts to the trans and 4 hex head cap screws to the driveshaft and we're good. On the Jag differential end, we also have a 4 bolt pattern, so the final piece is simple (we have some tricks to mate the GM driveshaft to the Jag diff). The slip feature of the driveshaft will go in the main tube, close to one end (in this case, the front). Since the diff is fixed in place, we have no real in/out movement so I had the driveline shop make the unit so we are only 1/2" beyond full compressed with the driveline installed. Here's a pic of the finished driveshaft

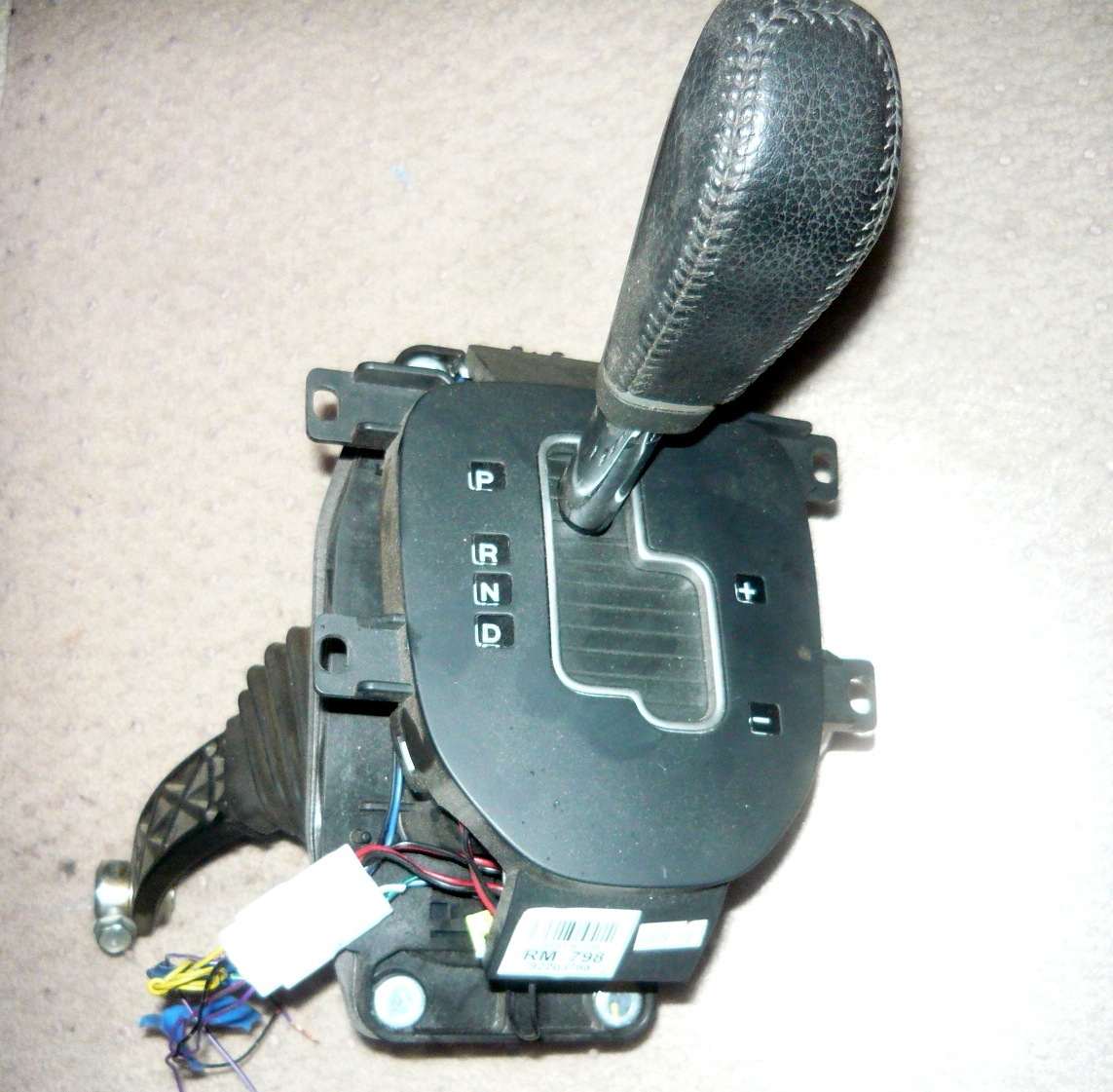

Shifter The shifter was an area I was looking forward to on this build, as this is the first time we would be using a 6 speed automatic transmission On the G8 itself, the shifter has 2 regions- the driver has manual control of P-R-N-D on the left side of the lever path and nothing lower than that. This leaves the transmission in full automatic mode, allowing the ECM and TCM to select the correct gears, 1-6, as required by load, speed, etc.,. However, from the D position, the driver can push the lever over to the right into a region that then has spring loaded positions above and below the D. This is the auto-manual position and here the driver can manually shift up or down as he wishes. Push forward to shift up and pull down to shift down. Each movement, up or down, shifts the trans one gear, ranging from 1 through 6, with an digital indicator on the dash showing the selected gear. Here's a pic of the G8 shifter itself so you can see what I mean:

So our challenge here is how to get this sort of format working with the Jag shifter. And I wanted to keep the Jag interior, and shifter, completely stock in appearance. But there was an unforeseen silver lining ahead. Even though the G8 shifter only allows the lever to move from P-R-N-D, the lever on the trans itself can do much more than that, shifting the trans to lower gears manually.. The Jag shifter is essentially a 4 speed shifter (even though the original Jag trans was a 5 speed, the shifting from 5 to 4 was done with an electrical switch, not a movement of the shift cable). After some tweaking of the XK8 LS conversion shifter parts, I was able to manually select gears P-R-N-D-5-4, which should be fine for basic operation (and is more than the standard application had). In the future, I'll wire in a momentary A-B switch to the ECM/TCM shifter input (done with a 12 volt supply and 3 different resistors on 1 wire to the controllers) to get the manual shift capability down to 1st gear and up again. But for now, we're done. As you can see from the pic below, the Jag shifter, and interior look completely standard....

That's it for this update. Stay tuned for first startup and next steps.... Want an LS-powered Jaguar for yourself?? Click the links below to Jaguar-LS conversion information on our website and a also photos of many different completed cars, most by our customers:

Gallery of completed LS-power Jags: http://www.jaguarspecialties.com/LS-gallery.asp

|